Quality Assurance

At our CNC hardware parts factory, quality is at the core of everything we do. From raw material inspection to final production, we follow strict quality control procedures to ensure every component meets international standards.

Our quality management system includes:

-

15S Quality Management to maintain a clean, efficient, and standardized production environment.

-

In-process Inspections to monitor production accuracy and consistency.

-

Incoming Material Inspection to ensure all raw materials meet required specifications.

-

Batch Production Procedures to guarantee stable and repeatable quality.

-

Regular Employee Training to strengthen skills and enhance awareness of quality standards.

To support these processes, we are equipped with advanced inspection instruments, including:

-

X-RAY Coating Thickness Gauge

-

Microscope

-

Electric Constant-Temperature Oven

-

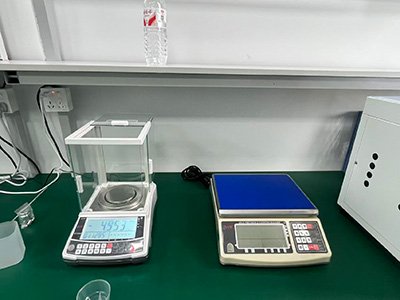

Analytical Balance

-

2D Vision Measuring Machine

-

3D Coordinate Measuring Machine (CMM)

With our comprehensive quality assurance system and state-of-the-art testing equipment, we ensure every CNC component we deliver is precise, durable, and reliable.

X-RAY Coating Thickness Gauge

Microscope

Electric Constant-Temperature Oven

Analytical Balance

2D Vision Measuring Machine

Coordinate Measuring Machine

Quality Inspection Department

Checking the quality of CNC components

Staff inspecting CNC products