CNC Metal Machining: A Comprehensive Guide

As manufacturing enters an era of high precision and efficiency, CNC metal machining has become the preferred process across numerous industries. Traditional workshops and ordinary machine tools can no longer meet the strict standards for complex, high-precision, and diverse batch metal components. CNC metal machining not only elevates product quality but also drives process innovation and industrial upgrades.

This guide explores the key processes, material adaptability, and essential considerations for selecting CNC metal machining services.

Technical Foundation and Principles of CNC Metal Machining

What is CNC Metal Machining?

CNC (Computer Numerical Control) metal machining is the automated, program-driven process of cutting, milling, turning, drilling, and tapping metal and plastic components. Pre-programmed instructions control machine movements, enabling high-quality batch production of complex parts.

Core Process Principles

CNC metal machining relies on the CNC system to convert CAD designs into executable CAM instructions, seamlessly integrating automatic feeding, rapid positioning, and high-speed cutting. Typical workflows include: process design → programming → loading & positioning → CNC machining → inspection → surface treatment → final packaging.

Differences from Traditional Machining

Compared to manual or conventional machining, CNC offers superior precision, efficiency, consistency, and the ability to handle complex structures. It is ideal for high-volume, multi-variety, and high-end custom metal parts production.

Equipment Types and Technological Advancements

Main Equipment Types

- CNC Lathes: Ideal for turning rotational parts with high precision and surface finish.

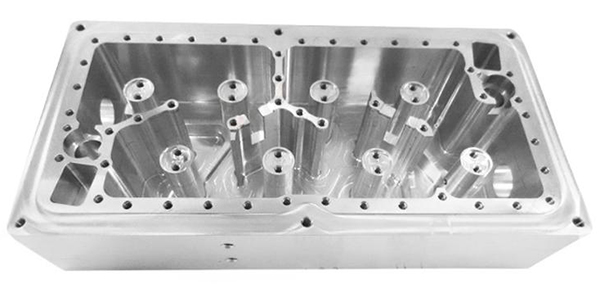

- CNC Milling Machines/Processing Centers: Suitable for flat, irregular, multi-hole, and multi-surface parts; capable of multi-axis operation with high efficiency.

- CNC Wire EDM: Used for precise machining of complex curves and thin-walled components, commonly applied in mold manufacturing.

- Laser and EDM Machines: Handle high-hardness materials and intricate shapes.

Automation and Smart Manufacturing

Modern CNC metal machining integrates automatic feeding, online inspection, intelligent scheduling, and remote monitoring to enable flexible, unmanned production.

Equipment Maintenance and Upgrades

Regular calibration and professional maintenance ensure machine precision and continuity. Adoption of five-axis machining, high-speed spindles, and other advanced models enhances competitive capabilities.

Material Adaptability and Process Features

Wide Material Compatibility

CNC metal machining can process stainless steel, aluminum alloys, copper, titanium alloys, plastics, magnesium alloys, carbon steel, and more, meeting requirements for corrosion resistance, strength, and lightweight design.

Material-Specific Strategies

- High-hardness materials (e.g., titanium alloys): Use high-strength tools and control cutting speed and feed.

- Aluminum alloys: Focus on chip removal and surface finish.

- Plastics: Prevent deformation and melting during machining.

Complex Structures and Precision

Multi-axis machining allows manufacturing of intricate geometries, spatially complex parts, and high-precision assemblies, meeting the custom component needs of electronics, automotive, and medical sectors.

CNC Metal Machining Workflow and Quality Management

Workflow and Process Control

- Design and Process Planning: Analyze part structure and performance requirements, choose suitable equipment and parameters.

- CNC Programming and Simulation: CAM software generates programs and simulates cutting to avoid interference and tool path conflicts.

- Loading and Precision Positioning: High-precision fixtures and automated feeding improve consistency and efficiency.

- Batch Machining and Quality Monitoring: Online inspection, automated data collection, first-piece verification, and batch sampling ensure product compliance.

- Surface Treatment and Finishing: Deburring, polishing, anodizing, plating, sandblasting enhance appearance and performance.

- Final Inspection and Packaging: Use CMMs, projectors, and other high-precision instruments to verify dimensions and appearance before shipment.

Quality Control Systems

Implement ISO9001 and traceable full-process management from raw material to delivery. Employee training and continuous process optimization enhance overall manufacturing quality.

Typical Applications of CNC Metal Machining

- Electronics & Communications: Precision connectors, housings, heat sinks, and microstructures requiring micron-level fit and batch consistency.

- Automotive Industry: Engine components, gearbox housings, chassis structures, and custom fixtures demand high strength and dimensional accuracy. CNC machining supports lightweight and modular automotive manufacturing.

- Medical & Bioengineering: Surgical instruments, implants, and analytical equipment parts require cleanliness and biocompatibility; CNC machining ensures precision and surface finish.

- Aerospace: High-strength structural parts, fuselage components, and precision connectors rely on CNC machining for efficient batch production of complex materials.

- Mold Manufacturing & Intelligent Equipment: Injection molds, stamping dies, and industrial automation equipment components depend on CNC metal machining for precision.

Customization and Industry Ecosystem

Flexible Production for Custom Orders

CNC machining providers can rapidly respond to small batches and multi-variety orders, from prototyping and design optimization to large-scale production.

Collaborative Supply Chains

CNC manufacturers work with material suppliers, surface treatment vendors, and logistics partners to ensure high efficiency, quick delivery, and market responsiveness.

Digital Transformation of Supply Chains

ERP and MES systems provide transparent management of orders, materials, production, and delivery, offering traceable and controllable services for clients.

Comparative Advantages and Core Value

Precision and Efficiency

CNC machining delivers micron-level accuracy and supports complex part formation, improving consistency and productivity.

Adaptability and Flexibility

Handles various materials and geometries, supporting custom, small-batch, and large-scale production, enabling diversified manufacturing.

Innovation and Process Upgrades

Integration of five-axis machining, high-speed spindles, and automatic tool changing meets high-end and emerging industry requirements.